Longoni Maple E71. Carom 71 cm

Longoni uses only the finest Canadian hard rock maple for the shafts. In winter the trees are cleared. Then the juice flows are almost stopped. The drying process starts immediately after harvesting. Then planks and beams are cut. This is done outside in

Longoni Maple E71. Carom 71 cm

Article code: 105205-71

2 reviewsadd your review

€76,92

€94,87

Delivery time: This is currently not available. Choose another variant.

Longoni uses only the finest Canadian hard rock maple for the shafts. In winter the trees are cleared. Then the juice flows are almost stopped. The drying process starts immediately after harvesting. Then planks and beams are cut. This is done outside in

More info

Product description

- Brand: LONGONI

- Article code: 105205-71

- Availability: Out of stock

- Delivery time: This is currently not available. Choose another variant.

| PRO, MAPLE & HB GAMING TRADITION Longoni's two-piece cue was born with the traditional wooden handle, in particular with the wooden joint derived from the famous French cue "Jolie". Despite the various technical changes that have been made, these axles are still available today and highly required. They are suitable for every discipline, for those who like to know their own game tool. |

| WITH A LONGONI SHAFT YOUR CHOICE IS NEVER WRONG The CLASSICS shafts are available in three wooden variants with different profiles and lengths to meet all needs in pole and carom (technical disciplines and 3C): The Pro specimens are made from the finest Canadian hard rock maple wood, selected for veining, weight and color; The Maple ones are a good compromise as they are produced with the same maple as the Pro shafts, but less selected: optimal playability with a more vintage look; The HB specimens are made of European hornbeam, which resembles hard rock maple, but is slightly harder and has a more gray color. |

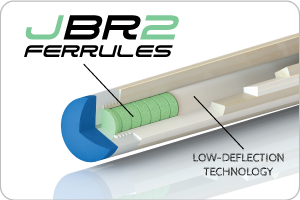

| JBR2 FERRULE, G10 CORE AND LD TECHNOLOGY Constantly improving the quality of the game is one of the main goals of the Longoni team. To ensure the maximum gaming performance of the Longoni axes, we worked a lot on their front end by introducing Longoni's new JBR2 ferrules with high-density G10 support and a proprietary system to reduce deflection and improve acoustics. |

| THE RIGHT PLACE FOR THE RIGHT WOOD This point is crucial: Stradivari was used to source the best wood in the valley of Panaveggio, where the spruce grew in a microclimate unique in the world. The Longoni company only uses the best hard rock maple from Quebec (Canda) and the whitest European hornbeam for its shafts, where extremely low temperatures, sunlight and soil provide the best quality wood for billiards. |

| CUTTING PROCESS The cutting of the trunks is done during the coldest times of the year to get the best physical characteristics and that white color that distinguishes the best shanks: the Longoni shanks. From the central parts of the boards are taken the elements that must have straight and thick holes without the presence of knots or other aesthetic imperfections, including the sugar streaks that can cause stains typical of the Saccharum maple. |

| DRYING PROCESS The drying process starts as soon as you cut the trunk into planks and leave them out in the open, in the extremely dry and freezing climate in which they are grown. Once the elements are removed from the planks, they are vacuum dried to mechanically remove most of the water retained by the cells. After the first run, all Longoni shafts are left in a special air-conditioned and constant drying room for a minimum of one year to completely drain the last traces of moisture before proceeding to the stabilization process. |

| STABILIZATION PROCESS Stabilizing the wood is the process by which the wood begins to absorb the natural ambient moisture from a fully dried material in order to achieve the right balance with the outside world. Thanks to this process, which takes a minimum of 3 months after the drying chamber process, the shafts remain stable over time and provide excellent playability. |

| CLASSIC SHAFTS LONGONI WARRANTY All Longoni shafts are warranted against manufacturing defects for two years on parts such as joint tightness, ferrule and ferrule. Every shaft is checked before shipment to be perfectly straight and to meet the strictest requirements of our customers. In case of deviations, our comprehensive after-sales service will provide you with all the assistance you need. |

| MADE WITH THE WORLD CHAMPIONS Longoni team players play an important role in the development of our shafts, as the skills of the best talents around the world allow us to create excellent shafts. All our models are tested and approved by our champions to ensure the maximum results and satisfaction for our customers. The results speak for themselves: our shafts have won the most important world-class titles. |

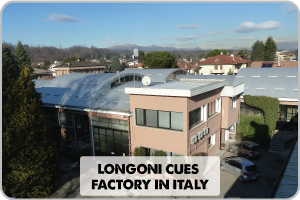

| MADE IN ITALY: YESTERDAY, TODAY AND TOMORROW All Longoni axes, including the laminated ones, are completely and uniquely produced in Italy at the Mariano Comense factory with techniques and machines developed by us. The processing cycle of each shaft takes a minimum of 24 months from the moment you cut the board to the moment it reaches billiards tables around the world. The choice to continue to manufacture entirely in Italy was motivated by the desire to have a product that differs from all others in terms of quality and technology, always under the strict control of our staff. |

| PRO SHAFT: PRECISION AND TRACEABILITY All Pro shafts are uniquely numbered to trace the production date. Each shank is also labeled to state the product specification, including code, name, diameter and exact weight. The label, in addition to showing this data, is a further guarantee of authenticity. Before labeling, each shaft is individually checked on a test table to prevent warping and other defects. To report the correct weight and diameter, we use a precision digital scale connected to the system and a laser micrometer. |

Reviews

jan huisman

Nog niet gebruikt

August 29, 2023 16:33

Jo van Herwijnen

Super top en pomerans

July 13, 2023 15:56